Cyclic (Perpetual) Stocktake:

For Perpetual Inventory, small numbers of items are counted on a daily basis, one or more times per annum, rather than carrying out a single complete stocktake on an annual basis.

The advantage of this method is that irregularities in the stock count can be corrected as they are detected which results in a more accurate day to day stockholding figure, stock reordering should be more accurately controlled and the need for an annual stock take may be negated.

The decision as to which items should be counted when and how often is based upon the Pareto principles whereby each stock item is given a classification or A,B,C or D based upon its gross usage value. The general rules for the classification are based around the principle that a small number of stocklines will account for the largest proportion of the usage value eg it has been known that as little as 5% of the total stocklines held have accounted for 80% of the usage value. These would commonly be classified as A, the next l5% of the usage value would be classified as B, the remainder either C if they have usage value or D if they have not been used in the preceding 12 month period. These latter items could be examined as to whether they should be reclassified as Non Stock Items so they are not included in the Daily Stock Re-Order processing.

The small number of A class items would be counted more frequently than those classified as B which in turn would be counted more often than those classified as C.

The Merlin system allows the user to determine the Stores which will be included in the cycle count process, the number of times each class of item is to be counted, the acceptable variances for quantity and stock on hand value and the number of times an item should be recounted before it is required to adjust the stock on hand.

To assist in determining the ABC classification of each item Merlin provides a report by descending gross usage value, which can be used to determine the value limits for each classification and consequently which items fall into which class. These limits may be used in update mode to update the actual stock classification or they can be used in a 'what if’ mode to determine the impact of varying the limits.

1. ABC Analysis

To access this screen:

Inventory

9. Reporting Procedures

5. ABC Analysis

Field 11. Mode - Enter `A'nalysis mode

Field 12. `A' limits and Field 13. `B' limits -Enter zero (See below for determining the limits)

<A>nalysis mode will run through the entire product file and generate a report file.

<R>eport mode - This has been replaced by the ICR.ABC.XML - ABC Analysis Report (below - Step 2).

<U>pdate mode will update the product file with A, B and C’s. Do not <U>pdate until you have set your A

and B limits.

Note: you can update at any time.

Option line: `F’

2. Determine the break points for A,B,C and D limits

Enter `REPORT’ in the main menu option line.

Enter `?' in Field 1 and a list of all available reports will appear.

Select ICR.ABC.XML - ABC Analysis Report

Field 2: Enter ID

Field 3: Enter the Main store (eg PH01)

Enter `R' to Run the report.

The report is found in the `Export' screen.

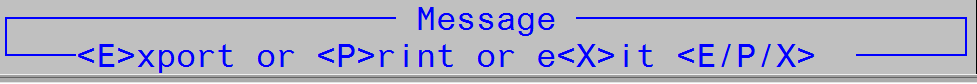

Zoom [EXPORT

Field 1: Task - Enter (nothing needs to be entered in this Field)

Field 2: Filter - Enter the date that the report was run in the format `20170721' or the name of the report.

Field 3: Drive\:Path: - Enter the path for the report to be exported to ie c:\merlin\reports

When the cursor is at the option line, type the reference for the report ie 4.1 (for line 1 of Field 4)

The `N' next to the report will change to `Y'

Now type `E' for Export in the option line and `Y' when the box opens.

The report will now be exported to the folder specified.

Using the report, determine your "A" and "B" limits.

To do this:

A: In the Cumulative % cost column, scroll down till the cumulative % cost tips over 80%. In that row, 2

columns to your left is the gross usage cost. This value will be your "A" limit.

B: In the Cumulative % cost column, scroll down till the cumulative % cost tips over 95%. In that row, 2

columns to your left is the gross usage cost. This value will be your "B" limit.

C: The last 5% of the gross usage cost is you “C” limit.

D: Dead Stock items – where gross usage costs are $0 or less than $0 (returns from prior periods).

3. Update the Stock records

Inventory

9. Reporting Procedures

5. ABC Analysis

Field 12.`A' limits - enter the $value derived from the report above

Field 13.`B' limits - enter the $value derived from the report above

File the screen

3. Activate Cycle Count

To access this screen:

Inventory

1.Maintenance Procedures

3.System File Maintenance

1.Inventory System

maintenance

15.Cycle count

Field 2: Site Code - add the store name and file.

Each site will have its own record in this screen

The cycle count processing task (ICT.CYCLE) is already setup in the task scheduler, so no need to do anything else.

The cycle count process that is run during end of day determines which items are due for counting on which day and produces count sheets on a weekly basis.

When an item has been scheduled to be counted, a snapshot of the stock on hand is stored in the work file at that point in time, and as each stock transaction occurs then the net movement from that point is also stored in the work file.

When the item has been counted and its count figure has been entered into the system, then the count is compared to the stored stock on hand plus the net movement. The difference is compared to both the allowed quantity and value variations and if it is within limits it is flagged as accepted. If it is outside these limits then it is scheduled to be recounted until it has been recounted the allowed number of times at which point if it is still outside the allowed variation then it is recommended that an adjustment be carried out.

On a weekly basis an activity summary is produced indicating how many items are to be counted for each classification, how many have been counted so far into the period, how many days are remaining in the period and the average number of items to be counted per day. The count sheets for the following week are also produced.

On a daily basis an action report is produced indicating for each item counted, whether the count has been accepted or if it should be re-counted or adjusted.

It should be noted that using Perpetual Inventory does not require any store to be 'locked' down whilst items are counted and all normal transaction processing may continue uninterrupted.